Automating processes with robots/automation is a great way to reallocate resources to safer tasks while improving productivity and quality, especially when you have an experienced robotic integration company at your side. FANUC Authorized System Integrators (ASI) is a trusted network of certified robotic solution providers who have the knowledge to identify your facility’s needs.

From simple automation systems to more complex cells, they will conduct a complete review of your system requirements. Then, they’ll use their expertise to design and install custom equipment, ensuring the largest gains in efficiency, safety and capital.

The robot integrator you choose helps determine the efficiency of automation at your facility. It’s important to learn a bit more about their specific experience and process, so asking a few questions beforehand is the best way to start. Here are five questions you should ask to maximize the benefits of working with a robotic systems integrator.

How Will Your Proposed Solution Ensure My Business’ Specific Requirements Are Met?

The best robotic systems integration is based on your business’ unique challenges. We listen to and understand these challenges, proposing the solution that will most help your business achieve its goals. Maybe it’s preparing products for shipping, streamlining parts assembly or creating an overall safer work environment. The right system can become a tailored solution to resolve challenges.

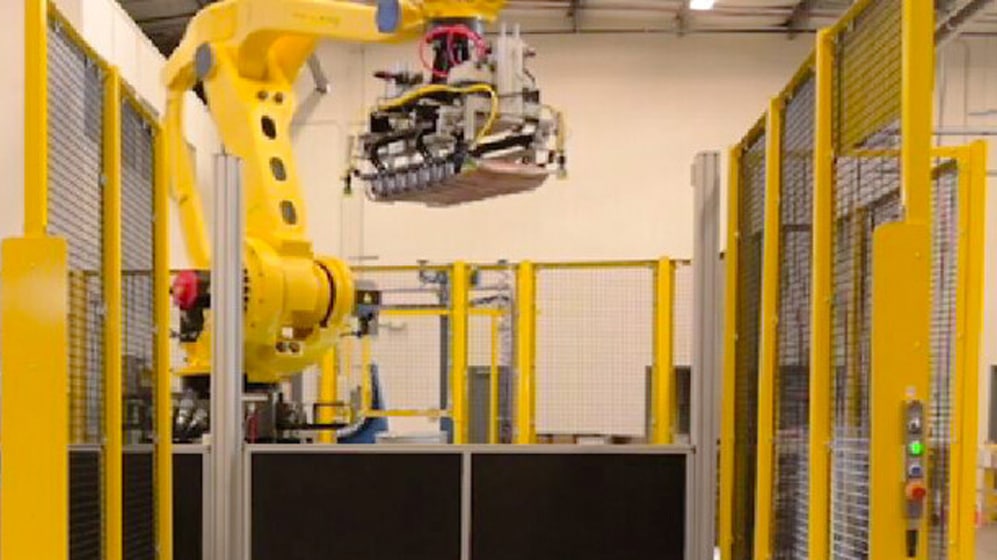

Our proposed palletizing robot system addresses the most common cause of back injuries–lifting heavy boxes. By having a robot do the heavy lifting, operators can work on other critical operations within your business, all while staying safe and injury-free.

How Much of Your System Is Your Integrator Willing to Work With?

Partner with someone who understands your business first-hand and is able and willing to meet your comprehensive efficiency goals. You’ll want to consult directly with your integration partner and avoid middlemen who can complicate the process and create delays with change orders.

Integrators offering in-house diverse expertise in packaging, scales, rack, material handling, and engineered solutions offer more innovative, big-picture solutions without losing sight of important details.

By keeping designs in-house, specialists work directly with you, resulting in quicker implementation and better outcomes. They also have first-hand experience with the system when providing maintenance and repair services that will ensure your industrial robots are operating at optimum levels.

What Certifications Do You Have?

Look for a certified robotic integrator when choosing your partner. Proper certification demonstrates that a robot integrator has experience working with leading robotic manufacturers like FANUC. It also illustrates they are up to date on crucial safety and efficiency training, two key elements to successfully integrating a robot into a process like manufacturing. In fact, nearly any application or industry regardless of scale and complexity can benefit from a robot integrated by a certified specialist. This versatility delivers precise results unmatched by others, translating to improvements that create safer work environments and stronger progress toward meeting operational goals.

What Industries Do You Have Experience With?

While many industrial robots are designed to perform a specific task, there is some measure of flexibility in their placement, like how a material handling robot can be integrated into a manufacturing process in various places where resources or products need to be adjusted. Having a robotic integrator with specific experience in your facility’s industry is ideal because they’ll be more aware of the different ways you can apply specific robotics. This kind of single-source integration offers a unique perspective on how to best integrate robotics, adequately addressing pain points and achieves optimal efficiency.

Choose an integrator who can help you increase throughput and extend operating times by designing systems specific to your industry needs.

- A single palletizing robot could be applied to the manufacturing, distribution, or packaging of products.

- Food-grade robots are environmentally protected and adhere to strictly regulated food and sanitation standards for dairy, bakery and meat production.

- Dispensing robots can apply adhesives and sealers with precision and efficiency unmatched by humans.

- Vision systems can assist with high-speed parts transfer, assembly and inspection for quality control.

These are just a few examples of how an experienced robotic integration partner can deliver solutions to automate nearly any task and process.

Securing a partner with experience in your industry ensures they know where to best place your investment. Choose someone with experience and demonstrated success in your specific industry, whether that be agriculture, food and beverage, manufacturing or distribution. Don’t hesitate to request more information about or examples of completed projects similar to yours to help you get a better sense of an integrator’s capabilities as it relates to your needs.

What Other Projects Have You Completed?

Learning more about other successful projects is a great way to verify that a robot integrator has the experience you need. Ideally, you’ll choose someone that can solve the problem at hand, whether it be highly specialized or big-picture concepts about your overall automation needs as they can demonstrate both variety and an extended history of satisfying clients’ goals. This proves they are adaptable as well as consistent. It’s also beneficial to choose a robotic systems integrator that offers a complete line of automation expertise, including in-house engineering, material handling, packaging, robotics, and equipment maintenance to provide seamless solutions.

RMH Is Your Single-Source Integration Partner

RMH has been helping companies work more efficiently for more than 80 years. Our customers come from a diverse range of industries all across the country. With a reputation for reliability, integrity, and ingenuity, RMH Systems is an ideal partner for robotics systems integration. Our multi-discipline process covers design, installation and upkeep for more reliable and in-depth support. Years from now, you can count on RMH’s devoted team of professionals to support your robotic and automation needs.

Request your free consultation with our engineers today to learn more. You can reach us by phone at 800-851-4995.