CUSTOM INDUSTRIAL CRANES TO LIFT AND MOVE YOUR PRODUCT

RMH Systems is a leading distributor of overhead bridge cranes and lifting equipment. Our overhead crane team is equipped with sales, structural engineering, CAD drafting, and service for your crane applications. Our product offerings provide reliable, heavy-duty, high-quality solutions to help your team be efficient and safe.

The information below is not comprehensive; if you have an application for industrial crane equipment, we have a solution, including service and repair.

Top-Running Cranes

In both single or double girder options, our overhead cranes provide reliability at exceptional load capacities. Available as electric overhead traveling cranes, or EOT cranes.

Underhung Cranes

Single girder design ideal for lower capacity applications that lack vertical clearance.

Workstation & Jib Cranes

Ergonomic options to service multiple workstations or easily handle product. Freestanding, ceiling-mounted or monorail design.

Gantry Cranes

Fixed or adjustable height options that make lifting heavy materials easy anywhere in your facility.

Monorail Cranes

Continuous runs of fixed, overhead tracks with trolleys equipped with hoists to lift, lower, or suspend materials.

Crane Hoists & Crane Trolleys

Solutions for any application: electric hoist, manual hoist, push trollies, hand geared trollies, manual lever, and more.

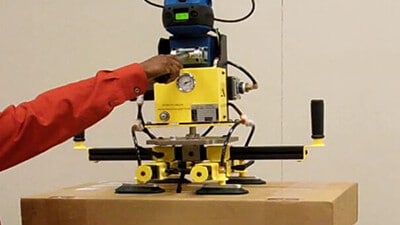

Below the Hook Lifting Devices

Rugged, durable, high-quality options for end effectors, load & spreader bars, and coil handling.

Intelligent Lifting Devices

Ergonomic devices that move with the operator. Ideal for high-cycle precise movements — Vacuum lifters, G-Force, Easy Arm.

CONTACT US

Fill out the form below to get in touch with our engineers.

Contact RMH Systems

"*" indicates required fields