As a private, regional or co-op owned beef harvest plant, you’re committed to sustainability, ethical treatment of cattle and providing quality meat. When it comes to working more efficiently and planning for future growth, you need a partner who understands your industry.

RMH Systems is one of the few systems integrators specializing in automation for the beef processing industry. And we’re the only one who handles your entire project in-house–from design, equipment selection, integration/controls, training and aftermarket service–and beyond.

Whether you need help creating the right facility design for a greenfield, brownfield, or making the most of existing space, our team of engineers, material handling, packaging, scales, & robotic experts provides a forward-thinking approach with a vision for future growth.

We’ll help you rethink your entire process by showing you just how much automation can improve your entire workflow, including conveyors, inkjet printing, case forming and sealing, and custom rack and storage solutions. These solutions can be customized to fit your current situation and grow with you in the future.

As a trusted partner to multiple regional beef processors, we’d love to talk with you more about how design, equipment, and automation can better position you for success today and in the future. Request a free consultation today to get started!

Request a Free Consultation

Our Beef Processing Automation Specialties

Whether you’re a co-op or owned by local farmers and ranchers, investor-owned or privately held, RMH is proud to be a trusted systems integration partner for regional beef processing plants across the nation.

Some of the areas we specialize in include:

Harvesting & Fabrication

Further Processing Lines

Primal Cuts

Ground Beef

Beef Tallow

Our Beef Processing Automation Solutions

Conveyor Systems

Reduce the need for manual handling and accelerate your workflow with a custom conveyor system, available in standard models as well as FDA-certified, washdown-ready stainless steel food-grade conveyors.

Product Coding & Marking

Automate your product coding and marking processes with continuous inkjet printers and other solutions.

Scales

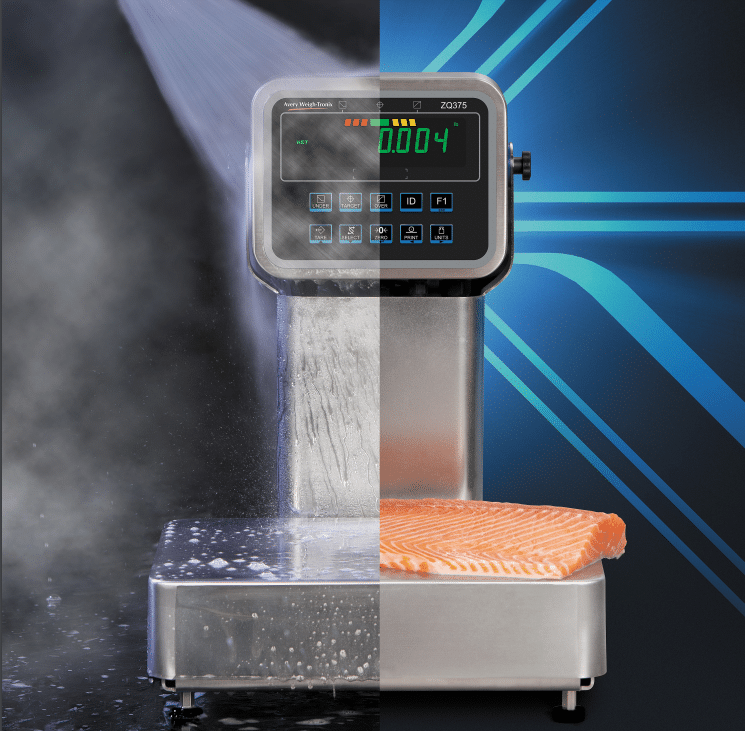

Offering a full range of custom industrial scale solutions, including high-speed checkweighers, deck scales, bench scales and truck scales. Options for legal for trade certifications or non-legal for trade, depending on your needs.

Case Forming & Sealing

Whether you use breaker boxes, regular slotted containers, two-piece boxes, or trays, we have a solution for case forming and sealing, with glue, tape or straps to hold cases shut.

Stretch Wrapping

Quickly and efficiently secure palletized loads with automated stretch wrappers. We have a solution to safely secure your loads for storage and transport, including simple semi-automatic wrappers on a dock or a high-speed fully automatic wrappers.

Warehouse Racking

Custom, heavy-duty warehouse racking designed to hold up to abuse in dry, cooler and freezer environments. We specialize in optimizing storage space through roll form and structural selective, drive-in, pushback and pallet flow racking, with less expensive options available for budget-constrained projects.

AS/RS

Efficiently store and retrieve beef products with automated storage and retrieval systems. Whether you need a full pallet of product or a unique mixed pallet, RMH can assist.

Palletizing Robots

Increase productivity, lower operating costs and create a safer work environment with palletizing robots.

Beef Processing Automation Projects We’ve Completed

RMH is a trusted partner for beef processors of all sizes across the country. Learn more about the automation projects we’ve completed for them.

Sustainable Beef & Schmeeckle Brothers

Ground Beef Greenfield Building Site – North Platte, NE

- Custom conveyor systems

- Automated case packing

- Industrial scale integration

- Storage rack systems

- Full controls and automation

Caviness Beef Packers

Ground Beef Greenfield Building Site – Amarillo, TX

- Lines and rack storage

- Added case formers, case sealers, in-motion scales, controls and integration

- Start-up and commissioning of existing panels that had been provisioned for this add-on

- Added new large format breaker box erector

- Designed heavy-duty galvanized pushback racking and selective racking with drip pans in between levels to prevent lower-level contamination in new cooler

- Added freezer drive-in drive through rack

- Added dry storage selective rack and pushback racking

Ground Beef Line Addition and Cooler Rack Storage – Kuna, ID

- Added duplicate of existing end-of-line systems

- Added case formers, case sealers, in-motion scales, controls and integration

- Start-up and commissioning of existing panels that had been provisioned for this add-on

- Added new large format breaker box erector

- Designed heavy-duty galvanized pushback racking and selective racking with drip pans in between levels to prevent lower-level contamination in new cooler

- Added freezer drive-in drive through rack

- Added dry storage selective rack and pushback racking

Ground Beef Addition at Greenfield Production Site – Kuna, ID

- Designed end-of-line solutions for new ground beef production

- Added case formers, case sealers, in-motion scales, controls and integration

- New panel start-up and commissioning

Phase III Sealer Room Retrofit – Hereford, TX

- Redesigned existing conveyor lines that were currently elevated

- Dropped existing lines to normal pass height to allow for easy operator intervention

- Conducted mechanical modifications, tear out, and re-install of conveyors for additional accumulation and improved throughput and merge

- Installed new control panel to clean up existing controls system and interlock with old panel

Phase II Sealer Room Retrofit – Hereford, TX

- Design and added third divert point to existing sorter

- Installed new conveyor and modified existing conveyors

- Added sorter and modified existing controls

Phase I Sealer Room Retrofit – Hereford, TX

- Redesigned solution to add two-divert narrow belt sorter

- Added new automatic ‘L’ Clip tape sealer for new box type

- Tore out and replaced conveyor sections to improve flow and reduce jams

- Installed of new gapper and sorter, and modified existing conveyors

- Added sorter controls and modified existing controls

Greenfield Production Site – Kuna, ID

- Designed case sealer room with improved efficiencies and layout

- Provided conveyor, “L” Clip Tape Sealers and controls

- Installed new system

- Controls, start up and commissioning of new system

New Box Erecting and Sealer Room – Hereford, TX

- Added Hytrol conveyors and controls

CONTACT US

Fill out the form below to get in touch with our engineers.