Key Takeaways

This article explains how solving common year-end material handling challenges—such as unfinished projects, deferred maintenance, inefficient layouts, and delayed automation—can help operations start 2026 with improved safety, efficiency, and ROI.

- Year-end is the ideal time to fix lingering material handling and warehouse issues before they turn into Q1 bottlenecks.

- Finishing small, high-impact projects now reduces downtime, safety risks, and operational friction heading into 2026.

- Larger initiatives, such as automation, layout reconfiguration, or major equipment upgrades, benefit from early planning and budgeting.

- Preventive maintenance completed before year-end helps avoid costly breakdowns during peak periods.

- Well-planned automation systems can pay for themselves in a few years and deliver strong ROI over their lifetime.

- Reviewing storage and space utilization can increase capacity and improve flow without expanding square footage.

- Stocking critical supplies and replacement parts before year-end prevents delays caused by early-year demand spikes.

While 2025 may be ending, you’re likely facing a lot of the same problems you said you’d solve this year. Daily demands make it easy to push projects down the list. But now, the deadline is here—and those projects still need your attention!

You’re not alone in these challenges, as we’ve heard similar stories from many of our customers. They’re often dealing with:

- Replacing damaged equipment: Warehouse racking that’s been beaten up by forklifts or end-of-line packaging equipment that’s worn out from heavy use.

- Improving operations: Making the switch to material handling automation and implementing industrial robotics solutions for better efficiency and safety.

- Maximizing budget: Making the most of their year-end budget or getting a head start on creating safer, more efficient workflows for next year.

That’s where RMH Systems comes in! Here are five problems customers like you commonly face and how our team of experts can help you solve them.

1. Finish Critical Projects Before They Become Bottlenecks

Now is the time to create a strategy to wrap up unfinished projects before they spill into a busy Q1, where they’ll be competing against fresh priorities, tighter timelines, and an even higher pressure to perform.

To avoid feeling overwhelmed, we recommend sorting projects so you can better prioritize how to spend your time and budget where it matters most.

| Priority | Status | Examples | Timeline | Impact |

|---|---|---|---|---|

| Finish now | Done or close to being done with little disruption. | Facility & Layout: Quick tweaks to improve flow. Picking & Workflow: Fast changes that cut travel time and errors. Packaging & Shipping: Simple fixes to speed pack-out. Equipment & Maintenance: Small repairs and overdue PM to prevent downtime. Safety & Compliance: Low-effort upgrades that reduce incidents. Systems & Process Cleanups: Housekeeping in WMS/SOPs. |

Low lift, high impact—completed quickly. Typically days or weeks (not months) because it doesn’t require permits or a full redesign. | Reduces daily frustrations or safety concerns immediately with little planning or investment required. |

| Pause and re-scope | Bigger initiatives with longer lead times or major investment. | Facility & Layout: Larger reconfigurations or expansions requiring design, permits, or downtime planning. Picking & Workflow: Process changes that impact multiple teams. Packaging & Shipping: New equipment or redesigned lines requiring capital approval and lead time. Equipment & Maintenance: Major equipment upgrades or replacements. Safety & Compliance: Facility-wide safety improvements. Systems & Process Cleanups: WMS upgrades, integrations, or automation projects. |

High lift, high impact—requires more planning. | Delivers major, lasting gains in capacity, throughput, and safety—but requires more planning and investment to execute properly |

2. Schedule Maintenance Now

Putting off maintenance for industrial equipment is one of the most common (and costly) end-of-year problems. It might save time today by ignoring worn equipment or outdated systems, but it will cost you more next year when it breaks down, often at the most inconvenient times.

By scheduling maintenance now, you’ll be able to:

- Reduce the need for reactive repairs and unexpected downtime during peak periods

- Improve safety and compliance, especially for equipment that requires annual inspection (overhead cranes) or calibration (industrial scales)

- Extend the life of existing equipment

If you’re behind, get caught up through RMH’s in-house team of factory-trained service technicians. We support all of our equipment systems through preventive maintenance and repair services.

3. Implement Automation to Improve Efficiency and Safety

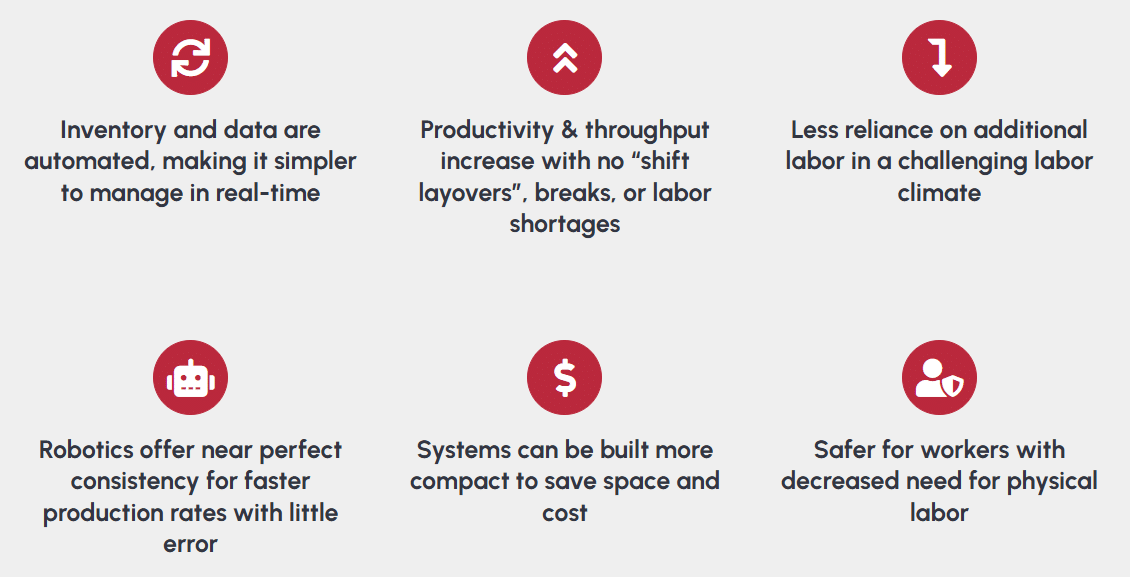

No matter your industry, automation is no longer a luxury. It’s a necessity for keeping up today and getting ahead in the future. Here are just a few benefits of automating in 2026.

With proper planning, automated systems can pay for themselves in a few years—or even sooner—by reducing labor costs, increasing throughput and minimizing errors.

Our experts at RMH can help you think through big issues with custom, intelligent solutions that solve problems like:

- Inefficient processes that slow down production

- Labor constraints that negatively affect productivity

- Scaling quickly for future growth or seasonal rushes

By automating critical processes, you’ll be able to meet growing demands, manage rising costs, and stay competitive in your market.

4. Evaluate Space Usage in Your Facility

What worked in the past may not be the best solution for today. With warehouse space at a premium, your facility must be optimized for today’s needs and future growth. Through RMH’s expert guidance, you’ll find that updating or reconfiguring your racking can:

- Improve inventory flow

- Increase storage capacity without requiring additional floor space

- Enhance safety

- Support higher volume

5. Stock Up Before End-of-Year or Q1 Rushes

Don’t wait until the last minute to make sure you have all the supplies you need and end up stressed because orders are delayed. Take inventory now and restock as necessary to ensure a smooth transition into 2026.

RMH is your one-stop shop for system integration, service, and even replacement parts. Here are just a few of the additional things we can help you with:

- Packaging equipment

- Safety equipment

- Replacement parts

- Consumables such as packing materials

With our 24-hour quick-ship program, we can deliver what you need quickly—well ahead of the industry-standard 72-hour turnaround. If you’re pressed for time, we’re ready to help you get things moving.

Expertly Prepare for 2026 with RMH Systems

RMH Systems excels at helping businesses solve today’s operational challenges while planning for tomorrow’s growth. When you’re planning for what’s next in 2026, now is the time to start the conversation with us. Request a free consultation today to begin building stronger, more efficient processes in the year to come.

Related Articles

Are Your Packaging and Material Handling Systems Ready for FSMA 204?

Key Takeaways FSMA 204 raises the bar for food traceability, requiring manufacturers to capture and maintain critical data at key points throughout production and distribution. While the regulation is often viewed as a software [...]

New Budget Law Accelerates Payback for Manufacturers: What You Need to Know

The newly signed One Big Beautiful Bill Act (OBBBA) makes it easier — and faster — for U.S. manufacturers to invest in automation, equipment, and even production buildings. For RMH Systems customers this means shorter [...]

RMH Systems Acquires Complete Solution Robotics, Expanding Automation and Robotics Capabilities

WAUKEE, Iowa – August 7, 2025 — RMH Systems (RMH), a leading provider of turnkey automation, material handling, packaging, and industrial scale solutions, has acquired Complete Solution Robotics, LLC (CSR), a respected robotics and automation [...]