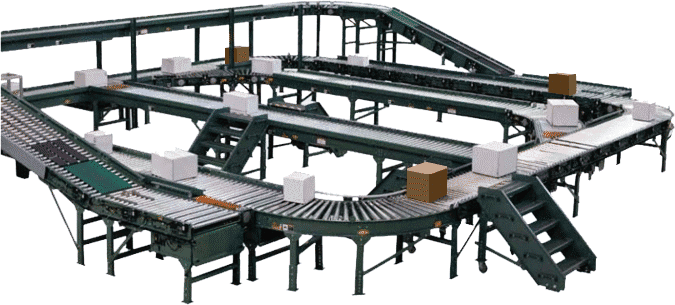

There is no one-size-fits-all solution for material handling and warehouse conveyor systems, but thankfully our friends at Hytrol helped outline how to find the right pallet handling solution for your needs!

What are you conveying?

The first thing you need to consider is what you are conveying. How heavy is it? How is it loaded on the pallet? How tall? Knowing the type and the orientation of the pallet directly affects how it is conveyed. Answering these questions will help you determine which conveyor system you need.

Where is it going to be conveyed?

While knowing what you are conveying is important, identifying where the conveyor will be, is also important. Will the conveyor need to withstand high temperatures? Low temperatures? Is the conveyor in a damp environment? Will the conveyor be around water? Conveyors have the ability to be built for virtually any environment, make sure your conveyor is built for your specific situation.

Pallet handling conveyor options:

Once you answer the questions above, you can begin researching the various pallet handling options that are available.

- Drag Chain: “Drag chain conveyors are used for heavy-duty pallet handling and are a good solution for loads that are not easily conveyed on roller conveyors. They can be configured as heavy-duty straight conveyors and integrate with Hytrol’s EZLogic® accumulation technology. These conveyors can handle load capacities of up to 6,000 lbs. and work in areas with increased temperatures.”

- Gravity: “Gravity conveyors are non-powered and utilize the Earth’s gravity to move products. They provide an economic material handling solution and are easy to install and relocate since they do not contain motorized parts. These conveyors use rollers or ball transfer tables to transport items. Their versatility, ease, and economic design have resulted in gravity conveyors becoming the most common conveyor used in the world.”

- Chain Driven Live Roller: “Chain driven live roller conveyors use a chain to drive the rollers and provide the power needed to move pallets. This heavy-duty roller conveyor can be integrated with transfers for angled transfer in a roller conveyor system. They work best for high load capacities and dirty or oily environments.”

- Poly-V: “Poly-V belt driven live roller conveyors, also called PLV, are an ideal solution for pallets, drums, or other bulk loads. They are optimal for light-duty pallet handling when low maintenance or a quieter conveyor is needed. The design of a poly-V belt creates a smooth, vibration-free solution with a long life. These conveyors are used for light- to heavy-duty pallet handling and have reduced noise levels.”

Having a complete understanding of your product, and the environment will be conveyed in, will help you choose the correct pallet solution for your conveyor system. Hytrol specialists, along with our own in-house conveyor specialists can help you decide on which conveyor option works best for your project.

Thanks again to Hytrol for this information, visit their website for more information on their extensive line of conveyors!

Want to automate your company? Find out how RMH Systems can boost your efficiency with custom made material handling systems packaging or robotic systems integration.