The Challenge

A well-known U.S. tool manufacturer was dedicating two full-time employees per shift to manually palletize hundreds of metal drawers—every day, across three shifts. The process was repetitive, physically demanding, and inefficient, especially given the complexity: over 100 drawer SKUs, reused slip sheets, and non-standard postal-style pallets.

They needed a smarter, safer, and more scalable solution.

The RMH Solution

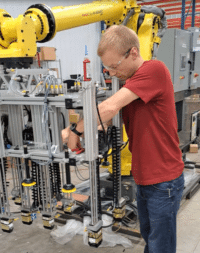

RMH Systems designed and installed a fully automated robotic palletizing cell tailored to their operation. Here’s what made it work:

- Custom EOAT (End-of-Arm Tooling): Designed and built to handle 147 unique drawer variants—ranging in size from 7”x13” to 26”x67”—including perforated models that required magnetic gripping. The same tool also picks heavily worn corrugated divider sheets and solid-body pallets with ease. An integrated mix of Magswitches and vacuum cups gives the EOAT the flexibility to reliably pick a wide variety of parts, no matter their condition or shape.

- Solid-Body Nestable Transport Pallets: The manufacturer used molded-foot pallets that required a conveyor system capable of handling this unique geometry. RMH Systems selected a plastic belt conveyor—commonly used for this pallet type—to ensure reliable transport and smooth integration with the robotic cell.

-

Fast, Flexible Deployment: Despite mid-project design changes and space constraints, the system was installed in just two days and fully operational by Day 3.

The Results

The Results

-

Manual palletizing eliminated across three shifts

-

Near-100% stacking accuracy

-

Improved ergonomics and operator safety

-

Labor reallocated to higher-value tasks

-

Scalable for future product variations or expansion

Why They Chose RMH Systems

The customer had worked with RMH in the past and trusted our ability to deliver. Our team’s deep experience in robotic integration, conveyor design, and custom tooling—along with strong project execution—made RMH the right partner to take this challenge from concept to reality. This successful automation project has opened the door for similar cells across their operation, driving even greater efficiency across their manufacturing lines.

Want to learn more or see this project in action? Click the button below.

Ready to Eliminate Manual Palletizing?

Let’s talk about how automation can work for your operation. Whether you’re dealing with labor shortages, repetitive tasks, or complex product handling—we design robotic systems that do the heavy lifting for you.

👉 Contact our automation team today and take the next step toward a safer, more efficient facility.

Related Articles

When Cattle Inventory Is Tight and Labor Is Tighter: How to Gain a Competitive Edge with Automation

Key Takeaways Beef processors are facing mounting pressure from tight cattle supplies and persistent labor shortages. For small to mid-sized operations, automation doesn’t have to mean replacing workers or investing in massive new systems. [...]

Choosing the Right Automation Partner: 4 Questions Every Regional Beef Processor Should Ask

Key Takeaways Automation can give regional beef processors a real competitive edge—but only when it’s right-sized and backed by the right partner. This blog outlines the key questions regional processors should ask when evaluating [...]

Automation ROI for Regional Beef Processors: Where to Start and What to Expect

Key Takeaways Beef processors are under increasing pressure from labor shortages, rising wages, and higher expectations for quality and sustainability. As a result, automation is being reevaluated—not as a simple cost-reduction tool, but as [...]

The Results

The Results